ALMINE 's product development policy is to challenge the unknown.

Instead of getting weighed down by theory, we looked directly at the problem and recognized the need for technology that balances quality and cost.

We then focused our attention on studying the continuous cast rolling method in greater depth.

We also realized that we need not limit our thinking to aluminium alone, but should seek answers outside that framework.

ALMINE's product development program, which is one of the best in the world, is already advancing into uncharted territory.

These are special alloys or the materials used to produce safety- critical components, which need strict quality.

例:2017 / 2024 / 3003 / 4047 / 6056 / 7075 他

| Size | Internal diameter/ External diameter/ Width(mm) |

Single weight |

|---|---|---|

| 7.0 〜 35Φ |

|

2,000kg |

|

1,000kg |

| Size | Internal diameter/ External diameter(mm) |

Single weight |

|---|---|---|

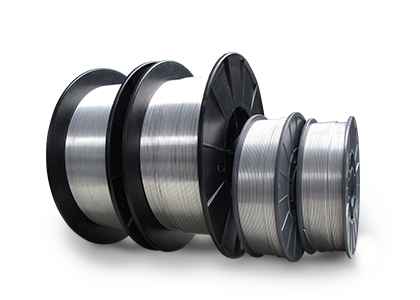

| 0.8〜1.8Φ |

|

MAX 20kg |

| 1.3〜3.0Φ |

|

MAX 40kg |

| 1.9〜6.5Φ |

|

MAX 50kg |

| 6.4〜25Φ |

|

①50〜200kg ②MAX 300kg |

| 22〜30Φ |

|

MAX 500kg |

| 7.0〜30Φ |

|

1,000〜2,000kg |

| Size | Internal diameter/ External diameter(mm) |

Single weight |

|---|---|---|

| 0.8〜1.8Φ |

|

MAX 80kg |

| 1.3〜3.0Φ |

|

MAX 200kg |

| 1.9〜6.5Φ |

|

MAX 200kg |

| 6.4〜25Φ |

|

①②MAX 500kg |

| 22〜30Φ |

|

MAX 500kg |

| Quality of the material | Size | Single weight |

|---|---|---|

| For thermal spray・aluminum wire for vapor deposition 99.99%AL 99.90%AL 99.70%AL AL-MG 5% Others |

0.1~4.0Φ | 2~200kg |

| Size | Internal diameter/ External diameter(mm) |

Single weight |

|---|---|---|

| 0.8〜1.8Φ |

|

MAX 60kg |

| 1.3〜3.0Φ |

|

MAX 100kg |

| 1.9〜6.5Φ |

|

MAX 150kg |

| Size |

|---|

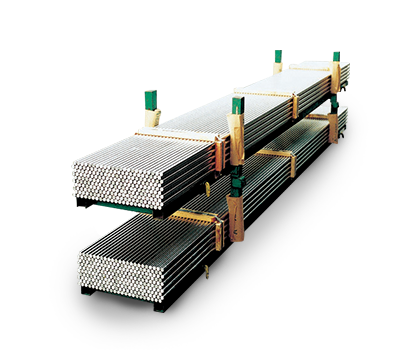

| 1.0〜35Φ × MAX 4,000L |

| Size |

|---|

| 0.2〜4.0T × MAX 1,040W × MAX 4,000L |

| Size | Internal diameter/ External diameter/ Width(mm) |

Single weight |

|---|---|---|

| 0.2〜4.0T × MAX1,040W × Coil |

|

MAX 5,000kg |

Up to now, we have been producing the thick diameters only in bar but we also succeeded in coil with 7000 series.

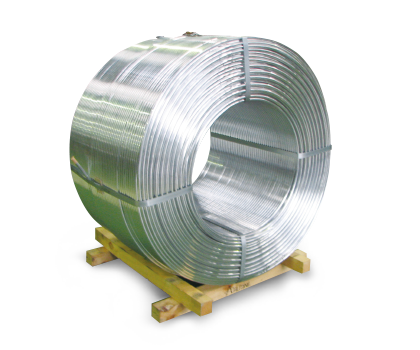

By unique Continuous Casting and Rolling method we are producing seamless wires up to diameters of 35mm, which are no defect and high quality coils with state-of-the-art technology.

Maximum weight : 2 metric tons

Use: automotive parts, aircraft parts and the others.

Features far better elongation and processing capability than conventional pure aluminium.

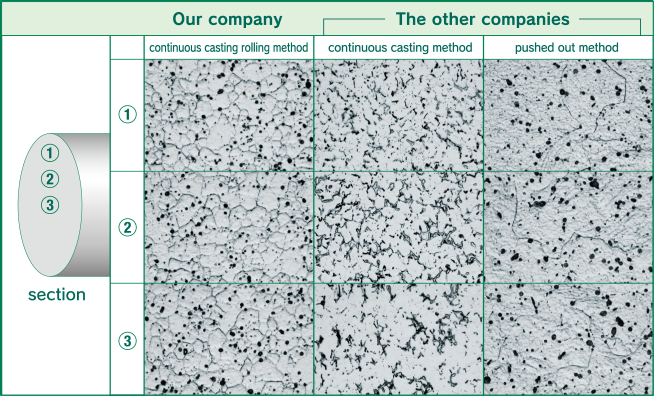

Almine succeeds in making the crystal grain of the metallographic structure super-minute in the continuous casting rolling method of the research and the company's in-house development.

The inside of a metallic organization is the segregation, and is also steady by a material that is more uniform than any process of manufacture of the other companies.

There is neither stress crack nor a stress distortion, too. It cuts, forges, and is preeminent.

As for the performance of the aluminum product, the uniformity of the metallographic structure is the most important.

The crack and bending occur if the remaining stress remains in a metallic organization where do the segregation of the alloy element,and it processes it, and it is likely to make trouble due to the secular distortion at times.

The material it is continuous and without a uniform organization and the segregation is made by the research and development in Almine.